Utlisation of Mussel Shell Waste as Partial Concrete Replacement

| ✅ Paper Type: Free Essay | ✅ Subject: Construction |

| ✅ Wordcount: 6801 words | ✅ Published: 18 May 2020 |

The Utilisation of New Zealand Greenshell Mussels – Perna Canaliculus Shell Waste as a Partial Concrete Replacement

The Utilisation of New Zealand Greenshell Mussels – Perna Canaliculus Shell Waste as a Partial Concrete Replacement

Table of Contents

Shells as a Concrete Component

Environmental Effects of Producing Cement

Bleeding Rate of Mix-Water in Saturated Concrete

Basic Thermal Properties of Concrete

Section A

Abstract

The goal of this project is to develop an alternative to cement using New Zealand Greenshell™ Mussels (PernaCanaliculus) shells by the end of the term. Using this wasted resource will indirectly reduce the use of raw materials as well as create a sustainable and cheaper construction material.

To investigate the properties of the proposed material, thorough research and a backyard test were conducted, testing the following: compressive strength, abrasion, density, fire resistance, thermal insulation, and trapped air in wet concrete.

Based on the research and tests, the shell powder samples’ performance was comparable to that of the ordinary concrete samples. The research and experimental investigation proved that shells can be implanted in concrete as a partial cement replacement, due to its high content of calcium carbonate. However, the addition of the shells must be done in small percentages namely, 5-20%, to prevent the material from crumbling.

Keywords: Building Material, Cement, Shells, Experimental Investigation, Quality System, Civil Engineering, Construction Industry

Overview

Background

Concrete is one of the oldest, most generally used construction material in the world. (Chemistry World, 2008) It plays a vital part in people’s daily lives, because it is used to construct buildings, like residential and commercial spaces. However, creating concrete and its components take a toll on the environment.

Portland cement, an essential constituent of concrete, leads to the release of carbon dioxide and different volatile organic compounds. In fact, the cement industry accounts for 5-7% of carbon dioxide emissions worldwide. (Rodgers, 2018)

Similarly, the extraction of limestone, a crucial element in cement, causes harm to the environment also as a health hazard for both humans and wildlife. Excessive quarrying could lead to a decrease of limestone provide, which can then make it difficult to provide adequate amounts of Portland cement. (Christie, 2015) This can result in all the employment associated with the concrete industry as well as new construction projects to be terminated.

One widespread sustainable innovation that may remedy the problem is through the use of the waste product in the concrete mix design. (Meyer, 2002) One such waste is shells, from molluscs or bivalves. New Zealand is home to 10 mussel species, however only one of those is cultivated. (FISHER, 2011). The New Zealand Mussel industry (NZMI) is based exclusively on the cultivation and harvest of Perna Canaliculus, (Trottier, 2013) the New Zealand Greenshell™ or green-lipped mussel. Perna Canaliculus is endemic to New Zealand and is found from the middle to low intertidal zones of rocky shores, to shallow subtidal areas of the North, South and Stewart Islands. (Dunphy, 2018) Green-lipped mussels are New Zealand’s major aquaculture species. In 2012, New Zealand mussel farmers exported 34 000 tonnes of green-lipped mussels, worth a total of $190 million. Compared, exports of latest Zealand’s other major aquaculture species like King salmon and Pacific oysters were worth $51 million and $15 million, respectively. (Science Learning Hub – Pokapū Akoranga Pūtaiao, 2013)

These shells are a non – biodegradable waste products which will utilise for such purpose. (DRAHL, 2019) These shells are thrown away in landfills or back to the water once the meat has been consumed.

This leads to the question: How can Civil Engineering remedy the problem?

Concrete is a versatile material, meaning it may be mixed with different elements to create a stronger and better end product. Since shells contain 95% calcium carbonate (CaCO3), which could be a component in cement making, and aids in the cement hydration process, it can be utilized in cement production and produce a stronger concrete sample. The proponent proposes the utilization of Perna Canaliculus shells as a partial cement replacement in the concrete mix design to alleviate the problem of waste disposal of the shells and also the environmental impacts of the production of cement. Perna Canaliculus shells are chosen because of its cementitious properties and abundance in New Zealand. Concrete technology should keep evolving to satisfy the increasing demands of all its uses. Creating it sustainable, means accounting for the short-term and long-term environmental consequences in design.

Concrete in Construction

Concrete being consequently universal in construction, finding ways in which to improve its properties or maintain them whereas managing to lower production prices would be very convenient and lucrative. Stone aggregate is usually expensive to acquire in locations that are isolated from adequate aggregate sources. Coastal communities nearby may greatly reduce the distance they have to transport aggregate materials reducing prices and there is an environmental impact.

Construction projects throughout the globe nowadays rely gradually on the use of concrete. The worldwide estimated consumption of concrete is 33 billion tonnes annually. This concrete is applied for projects of all sizes, starting from constructing dams to footpath. The primary components of concrete include water, cement paste, sand, rocks, and numerous admixtures. (World Business Council for Sustainable Development, 2009)

The mixture of these materials provides firm crystalline structures of calcium-silicate-hydrate. The most typical kind of concrete utilised in construction is called moderate-strength concrete with a compressive strength between 3000-6000 PSI (20-40MPa). Although concrete is not the strongest or toughest material on the market, the construction industry massively depends on its production. (WHD Microanalysis Consultants Ltd, 2005)

Concrete is used so abundantly in construction projects due to its relatively low price, long-term resistance to water erosion, and fire resistance. Due to the limited water erosion, concrete is suitable for building dams and structures exposed to constant rain. (Portland Cement Association, 2018) One more basis for the frequency of concrete usage is its mouldable property. Concrete is moulded into countless shapes and sizes reckoning on the design and state. Newly-made concrete is of a liquid type where the form and size are altered. (Morby, 2016) The most vital factor why concrete is used instead of different materials is price. Concrete can cost as very little as $80 per

, reckoning on material and transportation costs. (Allied Concrete, 2019) The materials needed to create concrete are rich almost everywhere on earth. Portland cement is usually composed of limestone powder mixed with clay and burned in an oven, which is affordable and promptly available. Lastly, one of the most necessary features of concrete is that it is fire-resistant. (Humanity Development Library, 2011) Safety is essential in building and designing liveable structures and concrete provides a durable, fire-resistant material for construction.

One of the main flaws of concrete is its weakness in tension. Concrete is extremely strong proportionally in compression, however weak in tension. Average compressive strength of concrete, at 28 days of curing, is between 3000 and 6000 PSI (20-40MPa) depending on the mix proportion. The tensile strength for uniformly batched concrete is between 300 and 700 PSI (2.0-4.8MPa). (Nemati, 2015) Concrete is about 10 times stronger in compression than it is in tension. To prevent tensile failure, steel bars are implanted into the mould of concrete to hold the tensile stresses. With this design, the concrete is not limited to its tensile fault. This design is termed reinforced concrete. (Grugel, 2008)

Shells as a Concrete Component

Mussel shell waster is taking up a large volume in landfills. If it is utilised in concrete mixes it will have a positive environmental impact.

This is helpful for the construction industry particularly since various admixtures like fly ash are studied for their potential negative environmental impact. (BRANZ, 2019) Mussel shells are considered into the aggregate category. Rather than using stones and sand as aggregates, mussel shells have the potential to produce the additional strength needed for construction design. The shells are a less expensive way to enhance the strength of concrete by producing a substance for the cement paste to bond. Mussel shells obtain their strength from a nacre layer that contains a crystalline structure in the type of calcium carbonate. (Australian Academy of Science, 2016) Replacement sand and stone with crushed shellfish shells may produce a recyclable alternative to discard shell waste.

Shellfish shells have progressed interest in studies revolving around the recycled concrete aggregate. (Setyowati, 2018) The reason why shellfish shells are part of this study is that they are simply available from the aquaculture industry and that they have chemical properties that make them enticing to the construction industry. After preliminary research, the shell that was chosen is the New Zealand Greenshell Mussels. The mussel shells were selected because of their physical properties additionally, as their availability.

The goal of the project is to develop an eco-friendly, cheap alternative to cement using Perna Canaliculus that will reduce the use of raw materials and create a sustainable construction material by the end of the term.

In achieving this goal, the study will address the following strategic objectives:

- To contribute to building knowledge and information about sustainable building materials applicable to New Zealand.

- To find a sustainable partial replacement for cement.

- To determine the properties of mussels

- To determine the adequate ratio and proportion to produce a concrete mixture with equal or greater performance.

- To initiate backyard testing as well as professional testing using the New Zealand Standards (NZS 3112.2:19860) to determine the properties of Shell concrete.

The study aims to discover the probability of using Perna Canaliculus shells as a partial replacement for cement in the concrete design process. It is considered important because creating modified cement with waste can indirectly reduce the use of raw materials and create sustainable construction materials.

Furthermore, this study will be significant to the following stakeholders:

The construction, engineering and design community are able to use shell waste as an alternative, sustainable and low-cost replacement for cement.

As engineers, for the sustainability, we should reduce the use of Portland cement in concrete, and instead use more blended cement, like using shells as an alternative cement replacement, that reduce greenhouse gas emissions and cannot contribute to the depletion of limestones.

The study focuses on utilising Perna Canaliculus shell waste as the main component of the building material. The properties of the material are analysed using qualitative and quantitative research methods. Testing is also done conforming with the New Zealand Standards. Cost and financial feasibility plans are considered in making the samples of the product.

- The exploration of other building materials will be limited

- The laboratory testing will be conducted using the available tools and products.

- The different species of mussel, oyster and clam shells will be omitted. Only Perna Canaliculus shells will be studied.

- Different types of cement products will not be tackled, only Type I Portland cement will be used

- The specimens will be tested 28 days only

The expected outcome of the study is to determine the right ratio and proportion for powdered Perna Canaliculus shells as a partial replacement for cement. It is hoped that this study will expound the knowledge of utilising waste materials as components in concrete design.

Environmental Effects of Producing Cement

The construction industry is a booming industry in New Zealand, particularly since the country embarks on the “Golden Age” of infrastructure. This industry is predicted to grow even additional due to the increased investment in infrastructure. This will then fuel the demand for cement and other construction materials required. This industry is expected to grow even more due to the increased investment in infrastructure. This will then fuel the demand for cement and other construction materials needed.

The cement industry expects the annual demand growth to grow by 2.2% increase by 2021. (Concrete NZ, 2018) This development will lead the demand for cement to alarmingly increase. Unfortunately, the production of cement contributes to air pollution, destroys the ecology, and affects human health. (NUNEZ, 2012)

Cement production produces 5-6% of all man-made emissions, 50% of which are emissions from de-carbonation and 40% from the fuel used to fire the kiln. The key polluting substances emitted to the air are dust particles, carbon oxides, nitrogen oxides (NOx) and sulphur dioxide (SO2). Polychlorinated dibenzo-p-dioxins and dibenzofurans, total organic carbon, metals, hydrogen chloride and hydrogen fluoride are emitted as well. (Rubenstein, 2012)

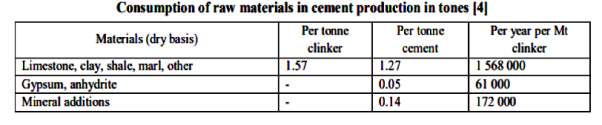

Figure 1: Cement Consumption of Raw Materials (INFINITY FOR CEMENT EQUIPMENT, 2017)

Additionally, cement manufacturing is a high-volume process. It consumes approximately 2.5 million tons of raw materials per year. Typically, 1.65 tons of limestone quarried for each ton of cement produced. (British Geological Survey , 2005)

Lastly, the destruction of the environment, production limestone mines for lime is completed through the use of explosives. Limestone mining use two kinds of blasting, small explosive and enormous explosive. Small explosive charges set along drilled lines free blocks of stone removed for construction. Massive charges reduce whole areas of limestone to rubble, removed for use as crushed stone.

Likewise, the disposal of waste in the New Zealand is an issue that requires serious attention. The aggressive pursuit for economic growth has resulted in the manufacturing, distribution and use of products that generate wastes that contribute to environmental degradation and global climate change. One such waste is Perna Canaliculus. These molluscs are produced and harvested in considerable amounts for human consumption, then discarded or reused.

Waste management is a fundamental issue that faces all industries in New Zealand and also the world. (Ministry of Primary Industries , 2018) The New Zealand Mussel trade (NZMI) generates solid waste product in the variety of a shell, undersize and rejected mussels, blue mussels, packaging wastes and epibionts that attach to the long lines adjacent to Perna Canaliculus Mussels. According to the New Zealand Mussel Trade Environment Code of Practice (NZMIECP), effective waste management ought to scrutinize all waste types created by this trade and apply the following:

- Reduce and avoid waste as it is currently produced

- Consider options for re-use of waste (recycling)

- Treat all waste before disposing

- Utilise ‘environmentally-friendly’ disposal options for the residual waste

In the New Zealand Mussel Industry Environmental Code of practice (NZMIECP), the NZMI identified principal waste varieties as packaging waste, mussel shell (as a by-product) and alternative solid waste as well as old machinery, office waste and containers. The shortage of inorganic waste is encouraging for an industry that endeavours to uphold the maxim ‘clean, green New Zealand’. However, the NZMI is aware of the quantity of shell waste it does produce and is consistently seeking sustainable, ‘eco-friendly’ ways that in which to recycle and reduce it. (The Ministry for Primary Industries, 1997)

In the New Zealand Mussel Industry Environmental Code of practice (NZMIECP), the NZMI identified principal waste varieties as packaging waste, mussel shell (as a by-product) and alternative solid waste as well as old machinery, office waste and containers. The shortage of inorganic waste is encouraging for an industry that endeavours to uphold the maxim ‘clean, green New Zealand’. However, the NZMI is aware of the quantity of shell waste it does produce and is consistently seeking sustainable, ‘eco-friendly’ ways that in which to recycle and reduce it. (The Ministry for Primary Industries, 1997)

Figure 2: Shell Waste at Havelock, Marlborough. This pile consists of waste shell produced by a local mussel factory as their principal means of disposal (Alfaro, 2002)

Cement is an important component in the construction industry as it is used to create concrete and mortars. However, manufacturing this material takes a toll on the environment. It causes pollution, destroys the ecology and affects the health of humans.

Likewise, the number of food waste produced by the country is enormously high, by 34%. included in that number are shells from clams, mussels and oysters, about 85%, being cultivated in New Zealand through aquaculture. New Zealand Greenshell™ Mussels Perna Canaliculus are a native New Zealand shellfish.

Scientific Testing

Tests are applied on the concrete, either in the laboratory or in the field, to determine its properties. This data could then be utilized in several ways: to determine whether the concrete complies with the requirements of a specification; to forecast how it will perform in service; to determine the result of various materials, or just to determine

Compressive Tests

Compressive tests on concrete are one of the most common concrete tests used by engineers. The compressive strength is determined by getting the failure load and dividing it by the cross-sectional area that is resisting the load. The units used for this test are either pound of force per square inch or megapascals. The average cement ranges from 3000 to 6000 PSI or 20 to 40MPa though, if it is in use, it can vary from 2500 to 10,000 PSI or 17.5 to 50 MPa. (National Ready Mixed Concrete Association, 2014)

Concrete cylinders or cubes are usually tested to guarantee the mixture suffices the specified compressive strength for it its intended use. These specified strengths are supposed to be obtained normally at 28 days. A test is sometimes conducted at 3 or 7 days as this can help identify issues that may be due to testing procedures. These tests happen because structural engineers need to design components of buildings, bridges, dams etc. To be sturdy enough to support everything safely. The figure 1 below displays a standard cylinder and cube loaded in the compressive testing machine.

Figure 4: Compressive Strength Test Equipment (Francisco, 2019)

The compressive strength is the most common strength test. In New Zealand, compression test specimens are typically 100mm diameter x 200mm high cylinders. Often 150mm diameter by 300mm high cylinders might use for a bigger aggregate of concrete.

When test specimens are fabricated, cured and crushed in accordance with NZS 3112 part 2. The 28-day test results characteristic compressive strengths of the conventional strength grades specified in NZS 3109 are N17.5, 20,25,30,35,40,45 AND 50 MPA. (Cement and Concrete Association of New Zealand , 1999)

Bleeding Rate of Mix-Water in Saturated Concrete

The method of determining the bleeding rate of concrete measures what proportion of mix water displaces from and accumulates on the surface of freshly poured and compacted wet cement, bleeding is caused by natural sedimentation of the solid elements before initial setting. (Goguen, 2014)

Tests for the bleeding characteristics of concrete are usually carried out in the laboratory to evaluate trial mixes or to evaluate the influence of various materials. The actual procedure is described in NZS 3112 part 1, Section 8. A sample of the concrete to be tested is positioned in a cylindrical container and compacted, either by rodding it or by vibration. The container is then enclosed and placed on a level surface. Bleed water is drawn off with a pipette at regular intervals till the amount collected throughout 30 minutes is less than 5 ml. The results could also be expressed either as the volume of bleed water collected during a given time per unit expanse of the cylinder or as a ratio of bleed water to total mixing water if the latter is known. (Ministry of Business, Innovation and Employment., 2010)

Trapped Air in Wet Concrete

Air pot testing is used to determine the proportion of air as a percentage in a fresh concrete mix and 4% to 4.5% air is standard. Values between 4.5% and 7.0% air will lead to a concrete that is 10% weaker than those with lower air contents. (Cement and Concrete Association of New Zealand , 1999)

Basic Thermal Properties of Concrete

Analysing heat conduction in concrete is imperative when considering energy-efficient building design, thermal loading of structures because of seasonal temperature fluctuations and in guaranteeing comfort for future inhabitants. (Uribe, 2015) It is also a vital predictor of cracking. Information of the thermal properties of a concrete product is significant in predicting temperature profiles and heat flow. The analysis of thermal properties is another quality control measure used for pre-cast structures and is important if such materials are to be utilised as in insulator. (Latta, 1962)

At thermal conduction, heat is conveyed in solid materials by free electrons and lattice vibration waves referred to as phonons. (Agency for Science, Technology and Research, 2003) During a conducting solid like a metal, the abundant free electrons convey a rise in kinetic energy once the heat is applied, before quickly transferring to cooler sections among the solid. (MIZUTANI, 2001) Some of this kinetic energy is conveyed to the solid’s atoms as a consequence of imperfections in the solid’s matrix. (Askeland, 2011) Non-metallic materials like concrete are thermal insulator as a result of they lack massive amounts of these free electrons to conduct heat. (Georgia State University , 2016) Any conductivity that will occur, but small, is administrated rather by the phono’s, and these are not as useful in the transport of heat energy as free-electron conduction, that happens readily in a metallic solid. (IMPRESS Education, 2002)

Cement and concrete products are porous. In ceramic materials which incorporates cement, porosity is assumed to have a powerful impact on thermal properties, wherein the greater the pore volume, the more decreased the thermal properties. Insulation needs a high level of electrical resistivity. (Asadi, 2018) Average room temperature electrical conductivity for dry concrete is

Ω-

. (Callister, 2003) This amount can be compared with polystyrene which has an electrical conductivity value of <

Ω-

, the chosen aggregate conductivities cover quartz with thermal properties of 4.45 kcal/m h°C, limestone 2.29 to 2.78 kcal/m h°C and basalt 2.47 kcal/m h°C. (Callister, 2003)

Curing

Curing is the process that regulates the loss of moisture from concrete once it has been set in position or the manufacture of concrete products, thereby rendering time for the hydration of the cement to occur. (HEARNS, 2019) Since the hydration of cement will take in days, and even weeks, instead of hours curing should be initiated for a few specific periods if the concrete is to attain its potential strength and durability. (Zemajtis, 2018) Curing may additionally comprehend the control of temperature since this influences the rate at which cement hydrates.

The curing period can rely on the properties needed of the concrete, the aim for which it is to be used, and the close conditions, i.e. the temperature and relative humidity of the surrounding atmosphere. ( The Concrete Countertop Institute, 2006) The curing of the concrete affects the strength gain of the concrete compared to standard curing of 28 days at 21 °C.

The effects of action are:

• Low temperatures for the first few hours after casting is probably going to extend the 28-day compressive strength.

• High early temperatures, either from atmospheric condition concreting, mass concrete or accelerated curing is probably going to lower the 28-day compressive strength.

Project Scope

Scope of the Project

The study focuses on utilising Perna Canaliculus shell waste as the main component of the building material. The properties of the material are analysed using qualitative and quantitative research methods. Testing is also done conforming with the New Zealand Standards. Cost and financial feasibility plans are considered in making the samples of the product.

Limitations of the Project

Since the time to research is limited, approximately 18 weeks, the study will not tackle the following influences:

- The exploration of other building materials will be limited

- The laboratory testing will be conducted using the available tools and products.

- The different species of mussel, oyster and clam shells will be omitted. Only Perna Canaliculus shells will be studied.

- Different types of cement products will not be tackled, only Type I Portland cement will be used.

- The specimens will be tested 28 days only.

Methodological Framework

Figure 5: Methodological Framework (Francisco, 2019)

Figure 6: Conceptual Framework (Francisco, 2019)

Figure 7: Materials Used in the Project (Francisco, 2019)

The materials used for the experiment are as follows: Cement, Sand, Gravel, Water, Perna Canaliculus shells, Trowel, mixing dish, Sealed Containers, Weighing Scale, Moulds, Sifter, Hammer, Mortar and Pestle.

Initial Procedure

This segment overviews each concrete test subject and it is testing procedures, this section includes the concrete mix design ratio, materials used, preparation of the mixes, integration of Perna Canaliculus in the mix and testing procedures.

This part provides the following samples used in the research.

Sample A – Conventional Concrete

Sample B – 5% Shell in Concrete

Sample C – 10% Shell in Concrete

Sample D – 15% Shell in Concrete

Sample E – 30% Shell in Concrete

Sample F – 50% Shell in Concrete

Figure 8: Concrete Samples Used (Francisco, 2019)

Preparation of Shells

Before the specimens are mixed, the shells must be prepared thoroughly and carefully. This is done by washing, drying and “cooking” the shells.

Collecting the Shell Waste

The shells were collected from restaurants located in Panmure, Auckland New Zealand.

Washing the Shells

The shells should be washed to get rid of the bacteria, leftover meat and also the smell. This can be done by boiling the shells in warm water for roughly 5-10 minutes per batch or hand-washing them using a brush and a cleaning agent with water. Between the hand washing and boiling, the handwashing was the most effective method as the proponent had additional control over the cleaning and removing the meat.

Additionally, to get rid of most of the odour attached to the shells the following methods is done: Freezing method, Bleaching method, and the Dish soap method. (Splad, 2017)

Figure 9: Washing and Boiling of Shells (Francisco, 2019)

Freezing Method

The first method is the freezing method. First, the shells must be boiled for 5 minutes to extract the meat and bacteria. Then, generously cover it with a drying solution made from 1 tablespoon of baking soda and 3 tablespoons of salt. Then, place the shells in a container and store it in the freezer.

Bleach Method

The second method was tested using the bleach method. First, prepare 4 cups of bleach, 4 cups of water and a tablespoon of dish soap in a large container. Mix the solution. Then, add the shells and leave it in the solution for 30 minutes. After 30 minutes, wash the shells in warm water and wipe using a cloth.

Figure 10: Bleach Method (Francisco, 2019)

Dish Soap Method

The last method used was the dish soap method. First, prepare one cup of dish soap, one cup of water, and a brush. Afterwards, put the shells in a solution and cleanse them mildly. Once fully soaped rinse using warm water and dry.

Figure 11: Dish Soap Method (Francisco, 2019)

Sun Drying the Shells

After washing the shells are left to fully dry to remove the odour under the sun for 2 days.

Figure 12: Sun Drying of Shells (Francisco, 2019)

Oven the Shells

Once all the shells are fully dried, it will be placed in the oven for 1 hour with a temperature of 500°C. This is performed to extract the calcium from the shells. The shells will have a lighter colour.

Various techniques were attempted to obtain the ideal temperature to extract the calcium carbonate from the shells. The shells were stored in a oven for 1 hr because according to some research this is the ideal time to leave the shells and extract its calcium carbonate.

Using a low temperature of 200°C the shells slightly lightened in colour, and do not easily crack using your hands. Adopting the 500°C temperature turned the mussels with an orange tint. Applying the 700°C temp, caused the shells to get burnt, a black in colour with a crumbly texture.

Another method of extracting the calcium carbonate from the shells is through a kiln. The kiln is constructed using a tray, 2 bricks, wire rack, 2 metal containers and a metal sheet. The temperature was approximate, 1000°C. Using this method resulted in a similar outcome, however, it took longer.

Figure 13: Oven the Shells (Francisco, 2019)

Pulverising the Shells

The shells are pulverised using a hammer until smaller pieces are produced. Then, shells are placed in a mortar and pestle to achieve a powdery texture. Based on experimentations and observations, the consistency of the shell does not affect the overall properties of the product.

The shells are pulverised using a hammer until smaller pieces are produced. Then, shells are placed in a mortar and pestle to achieve a powdery texture. Based on experimentations and observations, the consistency of the shell does not affect the overall properties of the product.

Figure 14: Manual Crushing of Shells (Francisco, 2019)

Sifting

After being pulverised manually ground-up powder is sifted using a 200MM sifter. The particles that pass through are used in the mix. The bigger pieces that don’t pass through are crushed again and sifted.

Figure 15: Sifting of Pulverised Shells (Francisco, 2019)

Sealing the Pulverised Shells

In order for the pulverised shells to be free of contaminants, they are directly stored in separate sealed containers until needed.

Figure 16: Sealing Pulverised Shells in Containers (Francisco, 2019)

Mix Design

In this section, the ratios for the control and shell mixes are explained.

Control Specimens

The control specimens are mixed using the typical ratio and proportion by volume, namely 1 cement: 2 sand: 3 aggregate: 0.5 water. A scale is used to accurately measure out the components.

Then the mixture is mixed thoroughly and placed in a mould as per New Zealand Concrete Construction Standard NZS 3109. The specimen is dried in a well-ventilated room, covered with cling wrap to avoid the water from evaporating. After 24 hours the samples are removed from their moulds and placed in a water bath until needed for testing.

Figure 17: Mixing Cement Procedure (Francisco, 2019)

Shell Specimens

The ratio of shells is done at 5%, 10%, 15%, 30% and 50%. These percentages are the measured out and are mixed in with the cement using a trowel. The aggregate and water ratios remained the same throughout all specimens.

Figure 18: Control Specimen Ingredients (Francisco, 2019)

Figure 19: 5% Ratio (Francisco, 2019)

Figure 20: Shell Mixing Procedure for Specimen (Francisco, 2019)

Self-Evaluation

Introduction

Ever since my college years, I have struggled with creating projects, writing topics and learning difficult subjects. Over the years, my writing abilities have progressed, and when granted time and an interesting subject that I can correlate too, I can write which may carry my ideas in a well-organized way, though my writing still has many areas for growth and support for details.

Strength

In this final project paper, I even have been able to organise my paper fairly. My final project is about the use of New Zealand green shell mussels (Perna Canaliculus) shell waste as a partial concrete replacement was a bit simple, I clearly expressed my background knowledge and was logically explained in the paper. The organization for the methodology section was hard as a result of the effect of the various scientific test result is the most important part of the study. As I furthermore put ideas and information, I had to keep improving some around as a result of I had to think about transitions and if I was making the point clear.

Weakness

Clarity is something I have to keep working on. When writing the final project, I hadn’t noticed anything wrong with it. As I read it over now, I see that it seems good in my head, however, leaves questions for the future readers. I had written the materials used for the project however provided no background regarding it and that I should not have assumed that was enough information. Keeping that in mind, when I wrote my final project paper about the use of New Zealand green shell mussels (Perna Canaliculus) shell waste as a partial concrete replacement, the shells used was not very well-identified, I made certain to clearly outline and explained the shell material, and justify the different uses of it. As I reread my draft paper, I saw a smooth flow of ideas that were not supported at all. There is also pieces of information written on the paper, however, there is hardly any description on that, with explanations of how it relates to the point I’m trying to create. Generally, I will make a point that I don’t have enough information to back up with. I had to do this in my second draft paper as a result of I had restricted information regarding some of the test done. I wrote very minimally about it and my point was not supported. This mistake helped me perceive how brainstorming is vital and that if I had brainstormed many other tests to write about, I would have been able to write good a final project paper.

Conclusion

I think I have refined my writing skills continuously throughout this course and hope I continue to improve my civil engineering knowledge and writing skills. I have been able to demonstrate good organisation in my papers, and can still work on learning the New Zealand Standards and on other civil engineering topics. I want to continue my career in civil engineering, and making this final project paper can help me in any sort of writing I do in the profession.

References

- Office of Infrastructure. (2005). Guide in Curing Cement . Retrieved from The Federal Highway Administration (FHWA) : http://www.pedbikeinfo.org/cms/downloads/Guide_for_CuringPavements_Vol1.pdf

- The Concrete Countertop Institute. (2006). Temperature and relative humidity: What they mean for you and your concrete countertops. Retrieved from Success with Creative Concrete : https://concretecountertopinstitute.com/free-training/temperature-and-relative-humidity-what-they-mean-for-you-and-your-concrete-countertops/

- Agency for Science, Technology and Research. (2003). Electrons play a key role in heat transport through 2-D tin sheets. Retrieved from Phys.org: https://phys.org/news/2017-02-electrons-key-role-d-tin.html

- Alfaro, A. (2002).

- Allied Concrete. (2019, August ). Concrete Calculator. Retrieved from Your Local Ready Mix Experts: https://www.alliedconcrete.co.nz/technical-info/tools/concrete-calculator/

- Amedeo Lancia, D. M. (2011). Calcium Sulfate. John Wiley & Sons, Inc., New York, 27.

- Asadi, I. (2018). Thermal conductivity of concrete – A review. Journal of Building Engineering, 1-13.

- Askeland, D. (2011). The Science and Engineering of Materials. Retrieved from Cengage Learning: http://home.ufam.edu.br/berti/nanomateriais/0495296023MaterialsEnginee.pdf

- Australian Academy of Science. (2016, May 12). She sells sea shells…. Retrieved from The secret life of one of the ocean’s wonders: https://www.science.org.au/curious/earth-environment/sea-shells

- BRANZ. (2019, July 9). Minimising waste. Retrieved from Level: http://www.level.org.nz/material-use/minimising-waste/

- Brewer, J. (2006). Scientific Principles. Retrieved from Materials Science and Technology: http://matse1.matse.illinois.edu/concrete/prin.html

- British Geological Survey . (2005). Mineral Profile . Retrieved from British Geological Survey : https://www.bgs.ac.uk/home.html?src=topNav

- British Geological Survey. (2005). The composition of limestone. Retrieved from British Geological Survey: https://www.bgs.ac.uk/discoveringGeology/geologyOfBritain/limestoneLandscapes/whatIsLimestone/composition.html

- Callister, W. D. (2003). Conductivity. In D. G. William D Callister, Material Science and Engineering. Wiley.

- Cement & Concrete Association of New Zealand. (2003). Cements. Retrieved from The Cement & Concrete Association of New: https://cdn.ymaws.com/concretenz.org.nz/resource/resmgr/docs/ccanz/ccanz_tm35.pdf

- Cement and Concrete Association of New Zealand . (1999). New Zealand Guide to Concrete Construction A publication of the Cement & Concrete Association of New Zealand . Retrieved from Cement and Concrete Association of New Zealand. : https://cdn.ymaws.com/concretenz.org.nz/resource/resmgr/docs/ccanz/ccanz_tm35.pdf

- Chemistry World. (2008, March ). The concrete conundrum. Retrieved from Chemistry World: https://www.rsc.org/images/Construction_tcm18-114530.pdf

- Christie, T. (2015). Mineral Commodity Report 21 – Limestone, marble and dolomite. Lower Hutt, New Zealand: Institute of Geological and Nuclear Sciences Ltd.

- Civil Engineering. (2013). Physical Properties of Cement. Retrieved from Civil Engineering: https://civiltoday.com/civil-engineering-materials/cement/111-properties-of-cement-physical-chemical-properties

- Concrete NZ. (2018). Cements . Retrieved from Concrete NZ: https://concretenz.org.nz/page/cements

- DRAHL, C. (2019, June). Chemists are finding better ways to extract biodegradable materials from crustaceans and insects. Retrieved from Science News: https://www.sciencenews.org/article/seafood-shells-chitin-plastic-food-waste

- Dunphy, B. (2018). Metabolomic analysis of heat-hardening in adult green-lipped mussel ( Perna canaliculus ): A key role for succinic acid and the GABA ergic synapse pathway. Journal of Thermal Biology, 1-74.

- Easley, C. (2016, July 9). Peak Photography by Clint Easley | Wall Art / Photographs / Pantheon Photographs. Retrieved from Fine Art America : https://fineartamerica.com/featured/the-pantheon-peak-photography-by-clint-easley.html

- FISHER, E. (2011). MUSSEL POWER. Retrieved from New Zealand Geographic: https://www.nzgeo.com/stories/mussel-power/

- Francisco, H. A. (2019). Shellment Project . Auckland , New Zealand : Haidee Anne Francisco – International College of Auckland .

- Georgia State University . (2016). Thermal Conductivity. Retrieved from HyperPhysics: http://hyperphysics.phy-astr.gsu.edu/hbase/thermo/thercond.html

- Goguen, C. (2014, September 17). Concrete Bleeding. Retrieved from National Precast Concrete Association: https://precast.org/2014/09/concrete-bleeding/

- Grugel, R. N. (2008, January). Sample records for concrete compressive strength. Retrieved from Science.gov: https://ntrs.nasa.gov/search.jsp?R=20090001885&hterms=concrete&qs=Ntx%3Dmode%2Bmatchall%26Ntk%3DAll%26N%3D0%26No%3D10%26Ntt%3Dconcrete

- HEARNS, A. (2019, January 4). Curing Techniques for Improving the Compressive Strength of Concrete. Retrieved from Giatec Scientific Inc.: https://www.giatecscientific.com/education/curing-techniques-for-measuring-the-compressive-strength-of-concrete/

- HeidelbergCement AG. (2010). Press Photos. Retrieved from HeidelbergCement: https://www.heidelbergcement.com/en/press-photos

- Humanity Development Library. (2011). Fundamental information on building materials. Retrieved from Humanity Development Library: http://www.nzdl.org/gsdlmod?e=d-00000-00—off-0hdl–00-0—-0-10-0—0—0direct-10—4——-0-0l–11-en-50—20-home—00-0-1-00-0-0-11-1-0utfZz-8-00-0-0-11-10-0utfZz-8-10&cl=CL1.1&d=HASH70c81f6386a2600bdfdd3f.3.9>=2

- IMPRESS Education. (2002). Conduction. Retrieved from Impress : http://www.spaceflight.esa.int/impress/text/education/Heat%20Transfer/Conduction%2002.html

- INFINITY FOR CEMENT EQUIPMENT. (2017). Raw materials used for Cement Production. Retrieved from INFINITY FOR CEMENT EQUIPMENT: https://www.cementequipment.org/home/raw-materials-used-cement-production/

- Latta, J. (1962, September ). CBD-93. Precast Concrete Walls – Problems With ConventionalDesign. Canadian Building Digest, pp. 1-9.

- Loe, D. (2014, January). Better Concrete Starting at the Finish: Long-term benefits of colloidal silica-based finishing. Retrieved from The Construction Specifier: https://www.constructionspecifier.com/better-concrete-starting-at-the-finish-long-term-benefits-of-colloidal-silica-based-finishing/

- Mahmud, I. (2012). 8 Main Cement Ingredients & Their Functions. Retrieved from Civil Engineering: https://civiltoday.com/civil-engineering-materials/cement/10-cement-ingredients-with-functions

- Meyer, C. (2002). Concrete as a Green Building Material. Retrieved from Columbia University: https://pdfs.semanticscholar.org/28a8/a01a5068bfb9b39ea6f3774e37bf17f0e117.pdf

- Ministry of Business, Innovation and Employment. (2010). Online Library. Retrieved from New Zealand Standards: https://www.standards.govt.nz/our-services/online-library/

- Ministry of Primary Industries . (2018, July ). Codes of practice and templates. Retrieved from Processing and handling/ Seafood/ Fish and seafood food safety codes of practice and templates: https://www.mpi.govt.nz/processing/seafood/codes-of-practice-and-templates/

- MIZUTANI, U. (2001). INTRODUCTION TO THE ELECTRON THEORY OF METALS . In U. MIZUTANI, INTRODUCTION TO THE ELECTRON THEORY OF METALS (pp. 60-70). Cambridge : Cambridge University Press.

- Morby, A. (2016, May 19). Fabric-cast concrete is the construction method of the future, say designers. Retrieved from Dezeen : https://www.dezeen.com/2016/05/19/ron-culver-joseph-sarafian-fabric-forms-cast-concrete-robotic-arms-construction-method-of-the-future/

- Nathan, S. (2006, June 6). Story: Mining and underground resources. Retrieved from Te Ara – The Encyclopedia of New Zealand : https://teara.govt.nz/en/mining-and-underground-resources/page-3

- National Ready Mixed Concrete Association. (2014). Concrete in Practice. Retrieved from NRMCA : https://www.nrmca.org/aboutconcrete/cips/35pr.pdf

- Nemati, P. K. (2015). Strength of Concrete. Retrieved from University of Washington : https://courses.washington.edu/cm425/strength.pdf

- NUNEZ, C. (2012). CLIMATE 101: AIR POLLUTION. Retrieved from National Geographic: https://www.nationalgeographic.com/environment/global-warming/pollution/

- Portland Cement Association. (2018). Spillways. Retrieved from Portland Cement Association (PCA): https://www.cement.org/cement-concrete-applications/water-resources/spillways

- Rice University. (2010). Hydration of Portland Cement. Retrieved from OpenStax Textbooks: https://cnx.org/contents/Lbv3xcBF@11/Hydration-of-Portland-Cement

- Rodgers, L. (2018, December 17). Climate change: The massive CO2 emitter you may not know about. Retrieved from BBC News: https://www.bbc.com/news/science-environment-46455844

- Rubenstein, M. (2012, May 9). Emissions from the Cement Industry. Retrieved from Columbia University: https://blogs.ei.columbia.edu/2012/05/09/emissions-from-the-cement-industry/

- Science Learning Hub – Pokapū Akoranga Pūtaiao. (2012). Limestone, a fizzy rock – introduction. Science Learning Hub , 4.

- Science Learning Hub – Pokapū Akoranga Pūtaiao. (2013, June 14). New Zealand’s green-lipped mussel industry. Retrieved from Science Learning Hub – Pokapū Akoranga Pūtaiao: https://www.sciencelearn.org.nz/resources/751-new-zealand-s-green-lipped-mussel-industry

- Setyowati. (2018). Concrete Made of Mussels Shell Waste Comparing Other Concretes as Architectural Design Components. Retrieved from SAO/NASA ADS Physics Abstract Service: http://adsabs.harvard.edu/abs/2018E3SWC..3105001S

- Sietse Bouma. (2015). Marine biodiversity stocktake of the. Hamilton City : Waikato Regional Council .

- SME. (2008). PRODUCTS CENTER. Retrieved from SME: https://www.elismeyers.be/production_of_cement_5113.html

- Splad, M. S. (2017). How to Clean Seashells Controversy. Retrieved from Seashells by Millhill: https://seashellsbymillhill.com/2014/07/29/how-to-clean-seashells-controversy/

- The Environmental Literacy Council. (2005, January 11). Cement. Retrieved from The Environmental Literacy Council: https://enviroliteracy.org/environment-society/materials-use/cement/

- The Ministry for Primary Industries. (1997). Fisheries New Zealand . Retrieved from The Ministry for Primary Industries: https://www.mpi.govt.nz/

- Trottier, O. (2013, June 25). New Zealand’s unique green-lipped mussels. Retrieved from Science Learning Hub: https://www.sciencelearn.org.nz/resources/513-farming-green-lipped-mussels-introduction

- Uribe, O. H. (2015). Smart Building: Decision Making Architecture for Thermal Energy Management. Sensors (Basel), 11-15.

- Webber, J. C. (2005). Annotated checklist of New Zealand Decapoda (Arthropoda: Crustacea). Research Associate, Museum of New Zealand Te Papa Tongarewa, 1-102.

- WHD Microanalysis Consultants Ltd. (2005). Cement hydration. Retrieved from UNDERSTANDING CEMENT: https://www.understanding-cement.com/hydration.html

- World Business Council for Sustainable Development. (2009, June ). The Cement Sustainability Initiative. Retrieved from ResearchGate: https://www.researchgate.net/post/Whats_the_annual_consumption_of_concrete_in_the_world

- Young, S. M. (1981). Composition of cement. Retrieved from The Pennsylvania State University : https://www.engr.psu.edu/ce/courses/ce584/concrete/library/construction/curing/Composition%20of%20cement.htm

- Zemajtis, J. Z. (2018). Role of Concrete Curing. Retrieved from Portland Cement Association: https://www.cement.org/learn/concrete-technology/concrete-construction/curing-in-construction

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allDMCA / Removal Request

If you are the original writer of this essay and no longer wish to have your work published on UKEssays.com then please click the following link to email our support team:

Request essay removal